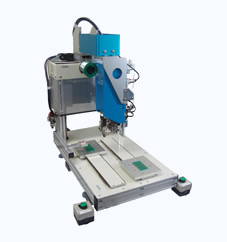

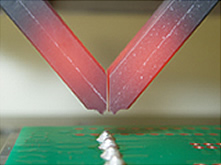

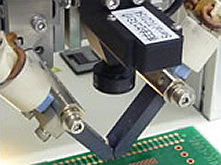

Point soldering unit

Useful for combination with other robot or automated production system

- Solder wire diameter

- φ0.3 - 1.6mm

- Solder cutting length

- 0.5 - 4mm

- Vertical stroke (up and down)

- Stepping motor type - 25mm/0.015mm steps

Servo system type - 25mm/0.012mm steps - Soldering tip

- Ceramic

- Heater wattage

- 100W x 2

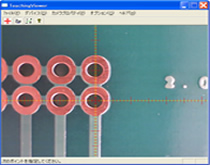

- Memory capacity

- PSU500RS - 255 points

*OPTION Max . 750 points - Machine interface

- 15PIN D-sub

- Weight

- MAX 8 Kg (included 1Kg solder wire bobbin)

- Data communications

- RS232C

- Solder feeding increment

- 0.08mm

- Number of cutting at one cycle

- 1 - 5 times

- Auto cleaning

- For heater channel and heater bottom (position)

- Heater temperature

- 400 - 800°C

- Input data

- 16data / 1point

- Block separation

- 16 blocks / 255 points

- Air input

- 0.5MPa (Dry air)

- Dimensions

- 140(W)、350(H)、200(D)mm