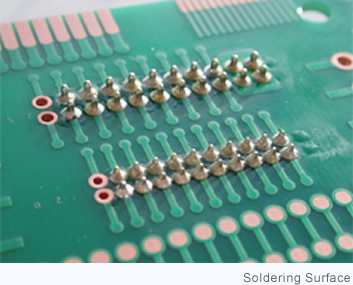

Why PSU500 is stable

for soldering ?

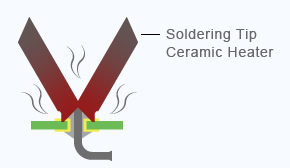

All-around “heat amount” stability is essentially important.

Cosmic’s point soldering robot system,

PSU500 can control “heat quantity” and

achieves the stability at soldering by following three methods: